- Home

- Case Study

- CEMENT PLANTS

Excavetor Shovel Hoom Crack Repair Welding.

Industry Type

Cement

Product Group

Lotherme

Our solution

Product

LOTHERM E 352

Size (mm)

3.15

Current (AMPs)

100

Qty. (Kgs)

4

Product

E 510 N

Size (mm)

4.00

Current (AMPs)

120

Qty. (Kgs)

8

Product

LOTHERM E 802

Size (mm)

4.00

Current (AMPs)

200

Qty. (Kgs)

6

ANALYSIS

EQUIPMENT

EXCAVETOR SHOVEL

COMPONENT NAME

BOOM

TYPE OF PROBLEM

CRACK

PROBLEM DUE TO

DYNAMIC LOAD HITTING

PREVIOUS SOLUTION

USING WITH 660 NH, NUCLOTECH 2222 N

BASE METAL

HI-TENSILE STEEL

COMP. WEIGHT (kgs)

ATTACHING WITH ORG EQUIPMENT

DIMENSIONS (mm) L * T * W

AS PER THERE DRG. * 30 * 500

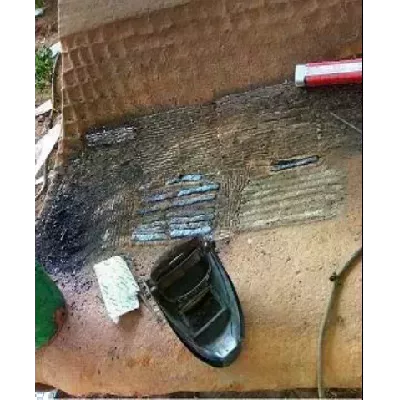

JOB PICTURES

Before

After

Further Reading on Case Studies

+919833550505

+919833550505

info@dnhsecheron.net

info@dnhsecheron.net