DEVELOPMENT OF BASIC COATED HP40Nb ELECTRODE

Published on 11 October 2022

DEVELOPMENT OF BASIC COATED HP40Nb ELECTRODE SUITABLE FOR HEAT AND CORROSION RESISTANCE CASTINGS.

1. Introduction

In petrochemical plants the welding consumable used in fabrication of

equipments grade such Alloy 20-32Nb (ASTM A351/ A351M-05) must

have good corrosion resistance, high heat resistance and improved hot

tensile strength along with good weldability properties to enable onsite

repairing. The petrochemical industry uses heat-resistant austenitic stainless

steels (Series H) for the fabrication of columns for water vapor reform

furnaces and pyrolysis furnaces. These furnaces are used for converting

water vapour into a hydrogen-rich gas which is then supplied to water

treatment plants to improve fuel quality or used in other applications.

Components used in petrochemical industry must continue in function for

long periods of time under severe environment. In view of this, a suitable

SMAW welding consumable with improved mechanical properties have

been developed in-house for fabricating HP-Nb modified (ASTM A297)

alloy or similar materials such as such as HT40, IN519, HK40. Continuous

research from many decades on these alloys made it possible to achieve

increased mechanical strength at high temperatures which has prolonged

their service life in sever environment Among various developments for

these steel is the addition of carbide forming alloy elements such as Nb, Ti,

Zr, W, rare earth mixtures and more recently, the addition of Y that are

stable at high temperatures. The high carbon content of these steels,

which is necessary for their high-temperature strength, gives these alloys

little mechanical conformability by conventional processes. It is therefore

necessary to characterize the microstructures of these materials to gain an

understanding of the behavior, morphology and composition of precipitated

carbides in order to relate these characteristics with the material properties.

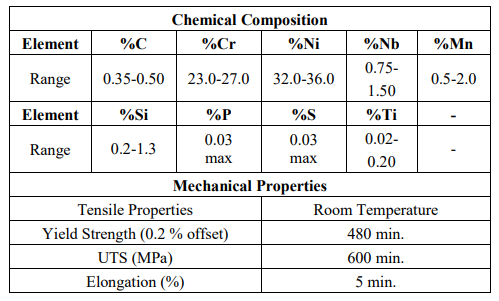

Table 1 - Specification to be Met as per Customers’ Requirement

2. Design of Product

Developmental work has been designed with performance of the weld to

meet the requirement of strength, hardness and toughness. Several trials

have been designed by keeping the following parameters in mind.

(i) Variation of chemistry within the specification limits.

(ii) Selection of high purity raw materials in flux formulation.

(iii) Performance characteristics of the product including slag detachability.

(iv) Control on S, P, Sn, Sb, & As to resist cracks.

(v) Selection of suitable core wire & its purity level.

3. Experimental Work

Several trials have been taken and established the weld metal chemistry to

meet customer’s requirement. Tramp elements are restricted to a very low

level and further reduced the Mn & Si content of the weld metal. The weld

metal composition meeting the requirement is confirmed by optical

emission spectroscopy. The all weld test coupons were prepared by these

electrodes. These test coupons are taken up for characterization and

mechanical property evaluations.

3.1 Preparation of Test Coupons

A small section of IS 2062 material with buttering is used as a base material

for joining purpose. A single V groove having 22.5 degree bevel angle is

made on the base plate. The all weld joint is supported with a backing strip

made of mild steel having dimension 155x35×6 mm same has been

buttered. In this study we have followed customer’s guidelines for

preparation of weld coupons. The welding parameters such as heat input,

preheat & interpass temperatures are controlled to get good quality welds.

The WPS followed are shown in the Table-2. The all weld test specimens

are machined out after x-ray from the each weld joint assembly and are

subjected to various tests including metallographic & mechanical testing.

Table 2 Details of the Welding Parameters Used in Present Study

3.2 Penetrant and Radiography Test

The weld deposits are analyzed with Dye penetration between the passes

and finally sent for X-ray for the evaluation of any presence of crack and

inclusions.

3.3 Tensile Test

The tensile property of the weld specimen is analyzed using AMSLER

Universal Tensile Testing Machine with a load capacity of 200 KN. The

tensile measurements have been conducted at room temperature (RT). The

round specimens of diameter 6.25 mm and gauge length of 25 mm used for

tensile testing prepared as per the AWS B4.0 standard.

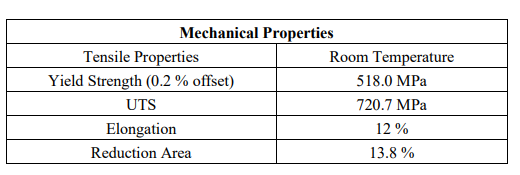

The tensile data is analyzed to estimate the yield strength (YS), ultimate

tensile strength (UTS), total elongation (TE) and RA (%). The tensile test

data as shown in Table-3 are analyzed to evaluate the ultimate tensile

strength (UTS), yield strength (YS), %elongation (EI) and reduction in

area.

Table 3 - Detail of All Weld Tensile Test Results

3.4 Hardness Test

A square base pyramid shaped diamond is used for testing in the Vickers

scale. Typically loads are very light, ranging from a few grams to one or

several kilograms. Hardness measurements were taken on the transverse

cross section of weld which covers weld region. Vickers hardness tester

was used with 10kg of indentation load, dwell time of 20 sec at room

temperature. Initially the surface of the weld samples were polished up to

1200 grit fineness followed by cloth polishing through 0.05μm grain size

alumina powder and finally etched. Readings of weld metal is shown in

Table-4.

Table 4 Vickers hardness test results (HV30)

3.5 Microstructure Analysis

In the as-welded condition the weld metal consists of austenite with eutectic

and secondary carbide. Alloy HP40Nb is not prone to sigma phase

Embrittlement and the presence of eutectic and secondary carbides in

austenitic matrix provides excellent hot strength and creep resistance in the

typical service temperature range. High levels of Cr and Ni provide good

resistance to oxidation and carburisation.

4. Discussion

In order to develop a suitable consumable for high heat resistance,

improved strength and good corrosion resistance, it is vital to develop a

weld metal chemistry that meets all requirements. According to the

necessities, consumable variables such as electrode size, flux and

composition have been established by continuous research and laboratory

testing. Careful optimization of the composition of weld metal and process

parameters such as current, voltage, speed yields good mechanical

properties and sound quality weld deposit. Evaluated testing results of weld

metal shows that The SMAW electrode developed in house has meet all the

requirements of as per customers’ specifications. The radiography and

liquid penetrant test have confirmed sound quality weld metal deposit.

Hence the careful optimization of weld metal chemical composition of

welding consumable and maintenance of weld metal quality makes this

product applicable for petrochemical industry applications as well as

various challenging structural applications.

5. Conclusion

- Suitable SMAW process consumables were developed for welding ASTM A297 - HP40Cb, HP and HP40 alloys or similar composition alloys.

- Consumables with lesser amount of P, S, As, Sn, and Sb yields good

strength & heat resistance.

×

Contact Us

Choose any option to contact us

-

Enquire Now

Enquire Now  +919833550505

+919833550505  [email protected]

[email protected]  Call on

+919833550505

Call on

+919833550505

+919833550505

+919833550505

8 min

8 min