Development of Basic Coated SMAW Electrode.

Published on 19 October 2022

Development of Basic Coated Shielded Metal Arc Welding Electrode Meeting AWS: SFA: E 16/8/2 Class with Corrosion and Toughness Requirements.

1. Introduction

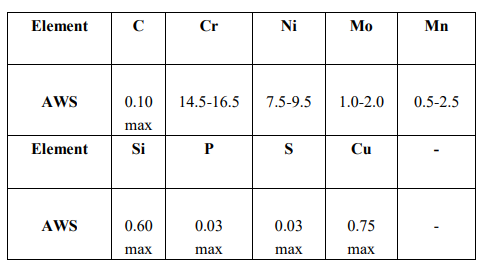

The nominal composition (wt %) of this weld metal is 15.5 Cr, 8.5 Ni,

1.5 Mo. These electrodes are used for welding stainless steels, such as

Types 16-8-2, 316, and 347, for high-temperature, high –pressure

piping systems and for dissimilar welding. The weld deposit generally

has a Ferrite Number in between 0 to 5 FN. The weld deposit produced

with these electrodes has good hot ductility properties that reduces

crater cracking problem even in high-restraint condition. The weld

metal is usable in as welded condition as per codes but it can also be

used in solution-treated condition. The chemical composition of these

electrodes should be balanced very carefully to develop their fullest

properties. In 16Cr-8Ni-1.5Mo properties include excellent high

temperature microstructural stability, high resistance to hot cracking at

very low ferrite (FN) levels, and good cryogenic toughness. Table 1

and Table 2 gives the AWS specification limits for SMAW (MMA)

weld metal.

Table 1 - Chemical composition of E 16-8-2-XX as per AWS SFA5.4

Table 2 - Mechanical properties of E 16-8-2-XX as per AWS SFA 5.4

During the primary phase of consumable development we faced

problem in percentage of elongation as per AWS standard. This

SMAW covered electrode fulfills the requirement of ASME section II

part C, which can be verified with the weld metal chemical

composition and mechanical property as shown in Table 1 and in Table

2. This advanced SMAW covered are characterized by a sophisticated

chemical composition that provides the weld metal with sufficient

impact toughness, Tensile strength with elongation. The Babcock and

Wilcox was the first company that published with reference to 16.8.2

depositing weld metal with about 0.07C-15.6Cr-8.2Ni-1.5Mo. [2] This

composition of weld metal is in the region of austenite „nose‟ of the

Austenite + Martensite (A+M) and Austenite + Ferrite (A+F)

boundaries in the Schaeffler diagram shown in figure 1, assuming 0.04-

0.1%C and constant values of 0.5%Si-1.5%Mn-0.05%N.

However, As per AWS A5.4 and A5.9 state that 16.8.2 weld metal has

usually below 5FN. The box shows that there is a mild chance of

martensite formation in the as-deposited weld metal yet there is no

confirmation that commercial weld metals contain martensite. In 1992

Kotecki corrects the misleading by proposed a new diagram in which

he examined the formation of martensite in composition. He developed

boundaries for 1wt% Mn, 4wt%Mn, and 10 wt% Mn. Since Mn does

not show up in the nickel equivalent of WRC-1992 diagram, a different

limit is required for every Mn level.

As per this new diagram of kotecki martensite-free microstructure of

16.8.2 is observed shown in Figure 2. The lower boundary of 16.8.2

composition box shows there is a probability of as-deposited

martensite. Diagram also includes coefficient of 0.25 for copper in the

nickel equivalent to observe the effect of copper content on ferrite

number.

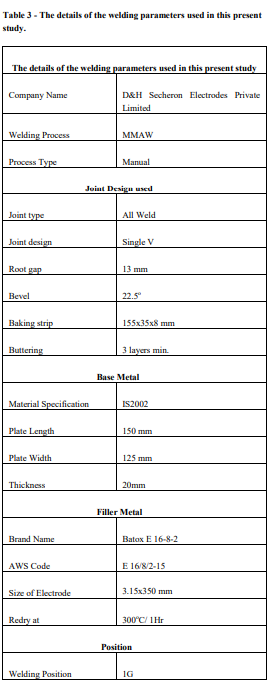

2. Experimental Work:

Several trials have been taken and established the weld metal chemistry

to improve the low temperature toughness tensile strength and

percentage elongation. The weld metal meeting the chemical

composition requirement is confirmed by optical emission

spectroscopy. The all weld test coupons were prepared by these

electrodes. These test coupons are taken up for characterization and

mechanical property evaluations.

The weld deposit after welding is evaluated with Dye penetration and

X-ray radiography as per ASME Sec V code. Defect free welded joints

were taken for mechanical testing. Once the mechanical properties

evaluation was completed, the weld cross section was cut in order to

characterize the weldment with macro structural analysis for

metallurgical study. For micro structural analysis the specimen was

milled, ground, polished and then etched using the Aqua regia reagent

(15 ml HCL, 5 ml nitric acid) and examined under the microscope.

2.1. Tensile Test

The tensile property of the weld specimen is analyzed using AMSLER

Universal Tensile Testing Machine with a load capacity of 200 kN. The

tensile measurements have been conducted at room temperature (RT).

The round specimens of diameter 12.45 mm and guage length 50 mm

used for tensile testing prepared as per the ASTM standard E-21. The

tensile data is analyzed to estimate the yield strength (YS), ultimate

tensile strength (UTS), total elongation (TE) and RA (%).

2.2. Metallographic Studies

The optical studies have been carried out using optical microscope.

Metallographic specimens have been prepared and cross section area

which is parallel and perpendicular to welding direction were polished

using various grades of emery papers and cloth with fine alumina

particles. This is followed by cleaning with distilled water and

methanol. The aqua regia etchant is used for observing the

microstructure is 65 % HCL and 35% HNO3 solution.

3. Results and Discussion:

In severe applications such as in Petrochemical, Chemical process

plants, Power generation industries a high performance weld metal is

required. The present study contains mechanical properties evaluation

of the high performance SMAW electrode is discussed and challenges

faced during consumable development. The tensile test is performed on

the pure weld deposit at room temperature, resulting values of tensile

test suggests that the tensile strength possessed by the weld specimen is

satisfactory for Petrochemical, Chemical process plants, Power

generation industries applications. From Table 1 it is clear that weld

metal strength is higher than the requirement.

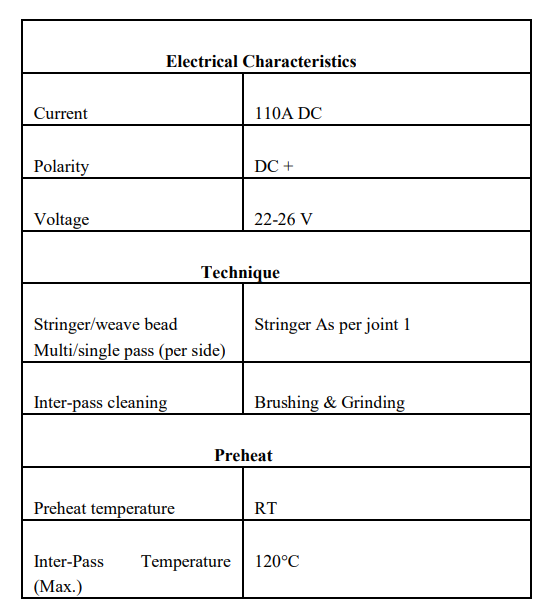

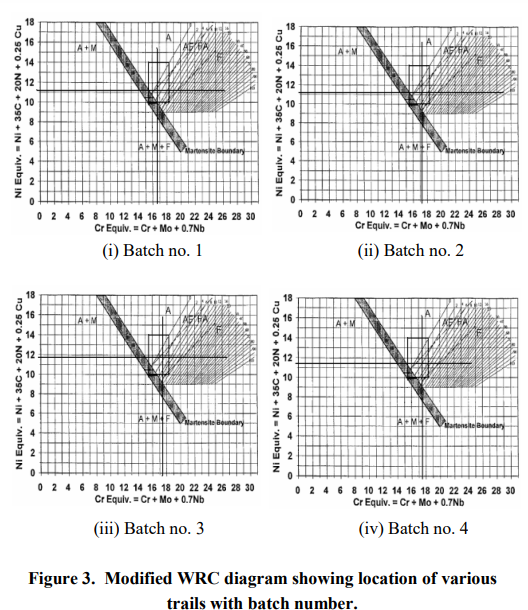

In Figure 3(i) and 3(ii) the composition of weld metal on modified

WRC-1992 diagram is near to martensite boundary zone with around

1%Mn that corresponds closely to as-deposited martensite resulting

lower ductility and brittle fracture even with higher ferrite number

where as if weld metal composition is shifted towards right as shown in

figure 3(iii) and 3(iv) resulting higher ductility and ductile fracture is

observed in tensile test even at very low ferrite number.

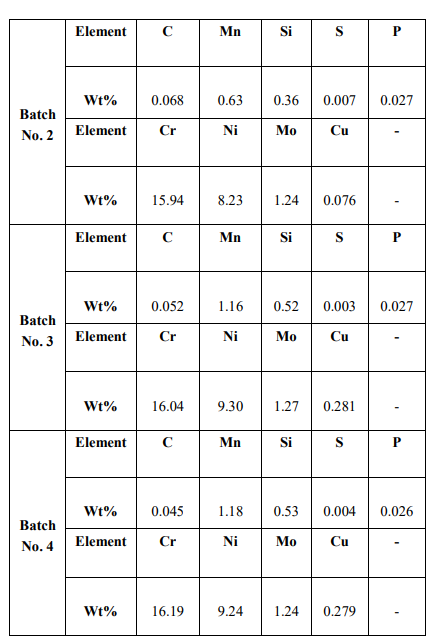

Table 4 - Weld deposit composition with various batches

3.1. Tensile Test

The figure shown in 4(a) and 4(b) is representative of brittle fracture

with a very little elongation whereas in figure 4(c) and 4(d) shows

ductile fracture with higher elongation.

The tensile test data as shown in Table 5 are analyzed to evaluate the

ultimate tensile strength (UTS), yield strength (YS), %elongation (EI)

and reduction in area.

It is clear from the tensile test results data that the batches with higher

chromium and nickel content as in batch 3 and batch 4 shows ductile

fracture as compare to batch 1 and batch 2.

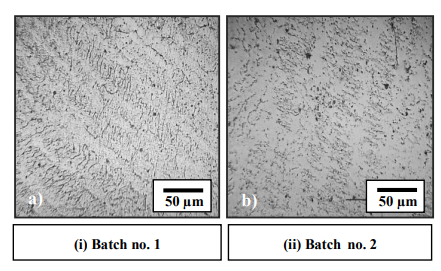

3.1. Microstructure

The weld metal microstructure consists with austenite and ferrite in

small proportion and there is no evidence of as-deposited martensite

formation in the weld metal but there should be a possibility of staininduced martensite formation if the composition of weld metal lies

close to the martensite boundary and if carbide precipates during post

weld heat treatment which leads to raise the martensite start

temperature. In figure 5(a) and 5(b) irregularities can be seen, these

irregularities in microstructure resulting brittle fracture or broke off

during tensile testing where as in fig 5(c) and 5(d) uniform

microstructure without irregularities gives ductile fracture in tensile

test. Microstructural stability is obtained by various combination of

composition with low ferrite number as show in figure 5.

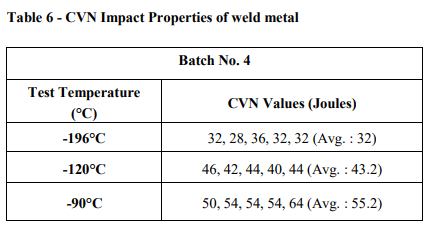

3.5 Charpy Impact Testing

For charpy impact testing, the specimens used are cut across the

welded joints having dimensions of 10×10×55 mm and type Vnotched, with 2mm of depth. The charpy impact test is performed as

per ASTM E23 standard to determine the toughness of the material.

Weld metal toughness values at -196°C, -120°C and at -90°C is show

in Table-6.

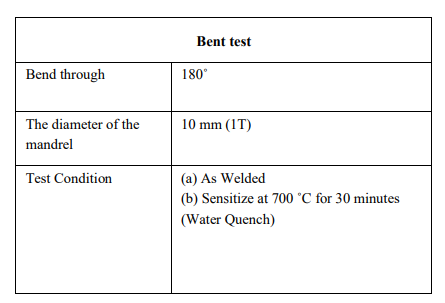

3.6 Inter-granular corrosion test

Susceptibility of weld metal produced with E-16/8/2 to intergranular

attack is determined by Practice E test as per ASTM-A262 standard.

The test has conducted on as-welded specimen as well as on specimen

after sensitizing heat treatment at 700oC for 30 minutes. The test

specimens are immersed in boiling solution of Cu-Copper Sulfate- 16%

Sulfuric acid for 15 hours. The test procedure is specified in Table 7.

To evaluate micro fissure and cracks 1T bend test has conducted on

specimens after exposed to acidified Cu-CuSO4 H2SO4 test solution.

The bent specimen has examined under 50x magnification is shown in

figure 6.

Metallographic examinations at 50x of the bent specimen showed that

there is no evident of micro fissure and cracks in as-welded specimen

and in specimen after sensitizing heat treatment at 700 deg C.

4. Conclusion:

Basic coated SMAW process consumable was developed in our lab

meeting AWS: SFA: E 16/8/2 -15 class requirements.

Optimum chemistry required for meeting percentage elongation,

corrosion practice E and toughness even at -196°C were formulated.

×

Contact Us

Choose any option to contact us

-

Enquire Now

Enquire Now  +919833550505

+919833550505  [email protected]

[email protected]  Call on

+919833550505

Call on

+919833550505

+919833550505

+919833550505

8 min

8 min